Chilie Rapid CNC Machining Service

Supply reliable quality and quick response on precision machining and assembly parts to support our customers focus on their business and develop their market.

What is CNC Machining?Chilie Rapid CNC Machining Service

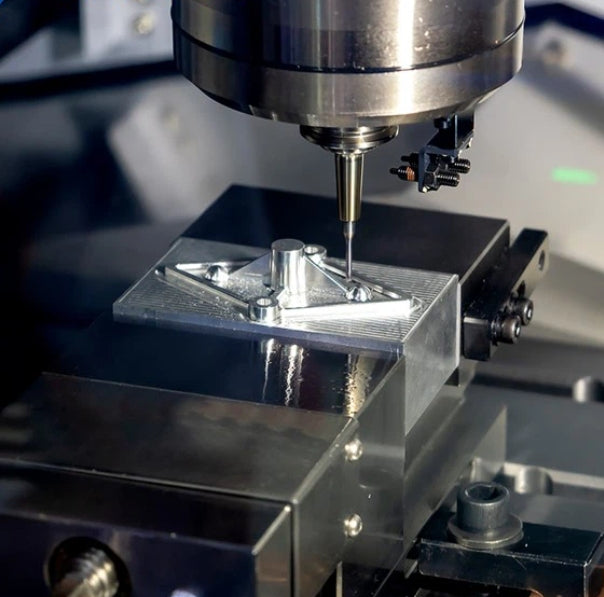

CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process can control a variety of complex machinery, including grinders, lathes, mills, and routers, with unparalleled accuracy and consistency. Unlike conventional manual machining techniques, CNC machining automates the manufacturing process, resulting in higher productivity, reduced waste, and enhanced precision.

How Does CNC Machining Work?

At the heart of CNC machining lies its programming prowess. Design specifications are translated into computer-aided design (CAD) files, which are then converted into instructions for the CNC machine through computer-aided manufacturing (CAM) software. These instructions dictate the precise movements and actions of the machine's tools, guiding them through the material to achieve the desired shape and dimensions. With CNC machining, manufacturers can produce intricate and complex parts with minimal human intervention, ensuring repeatability and precision at scale.

Key Advantages of CNC Machining:

- Precision: CNC machining offers unparalleled precision, allowing for the production of parts with tight tolerances and intricate geometries.

- Efficiency: Automation reduces production time and minimizes human error, resulting in higher efficiency and lower manufacturing costs.

- Versatility: CNC machines can work with a wide range of materials, including metals, plastics, composites, and wood, making them suitable for diverse industries.

- Scalability: CNC machining is highly scalable, enabling manufacturers to produce small batches or mass-produce parts with equal ease.

- Complexity: With multi-axis capabilities, CNC machines can produce highly complex parts that would be challenging or impossible to achieve using traditional methods.

- Consistency: The automated nature of CNC machining ensures consistent quality across all produced parts, eliminating variations caused by human error.

Applications of CNC Machining:

CNC machining finds applications across various industries, including aerospace, automotive, medical, electronics, and prototyping. From producing precision components for aircraft engines to crafting intricate medical implants, CNC machining plays a vital role in driving innovation and advancing technology.

Why choose Chilie's CNC machining services

- Quick turnaround

- High accurate and can be repeated in exactly the same manner over and over again

- Quick remove large amount of spare materials

- Wide range of materials,variety of plastics and metals

- Small and micro parts

- Low investment in tooling making and preparation

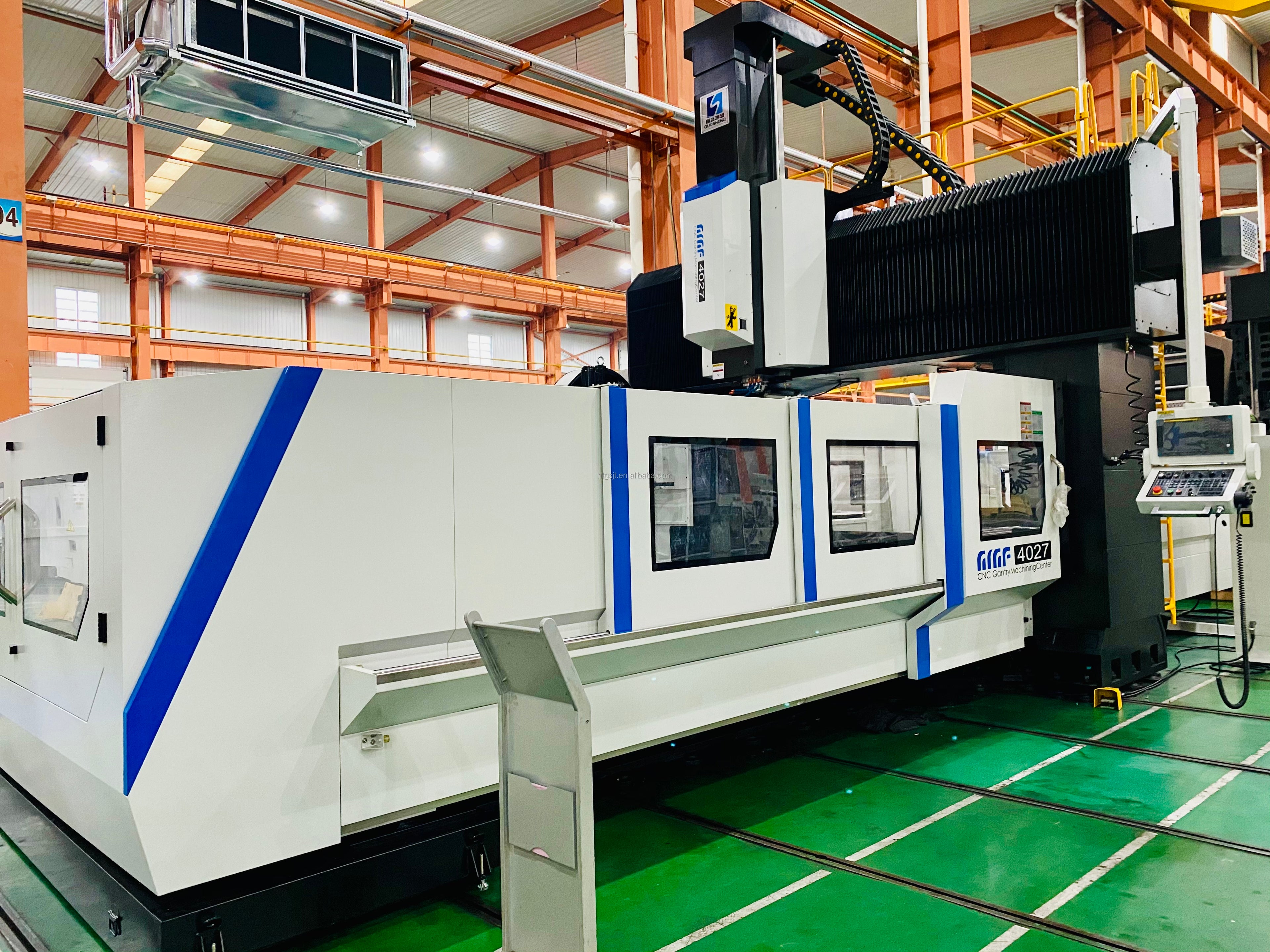

CNC Milling Machining

- Machinery Axis: 3,4,5,6

- Tolerance:+/- 0.01mm

- Special Areas : +/-0.005mm

- Surface Roughness: Ra 0.1~3.2

- Supply Ability:500000Piece/Month

- 1-Piece Minimum Order

- 3-Hour Quotation

- Samples: 1-3 Days

- Lead time: 7-14 Days

CNC Turning Machining

- Machinery Axis: 3,4,5,6

- Tolerance:+/- 0.01mm

- Special Areas : +/-0.005mm

- Surface Roughness: Ra 0.1~3.2

- Supply Ability:500000Piece/Month

- 1-Piece Minimum Order

- 3-Hour Quotation

- Samples: 1-3 Days

- Lead time: 7-14 Days

CNC Machined Parts Service

- Precision Machining Parts

- Machinery Axis: 3,4,5,6

- Tolerance:+/-0.01mm

- Special Areas:+/-0.005mm

- Surface Roughness: Ra 0.1~3.2

- 3-Hour Quotation

- Samples: 1-3 Days

- Lead time: 7-14 Days